System WorkFlow

Introduction

The purpose of this document is integral within the broader framework of the Complete Solution Guide: Smart Station by Hidden Brains. Its primary aim is to provide an essential resource for a thorough understanding of the system by offering detailed insights into system overviews and workflows.

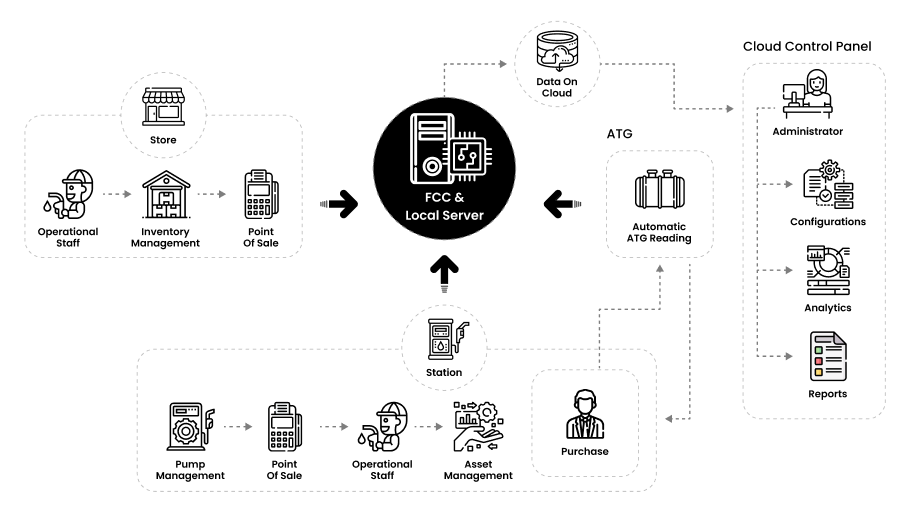

System Architecture Visualization: The document includes illustrative elements depicting the system’s architecture. These visuals showcase modules, components, and subsystems, enhancing comprehension of the overall structure through visual representation.

System Overview: A high-level overview of the Smart Station System is presented, offering insights into its purpose, functionalities, and role within the broader organizational framework. This section provides context to understand the significance of the system.

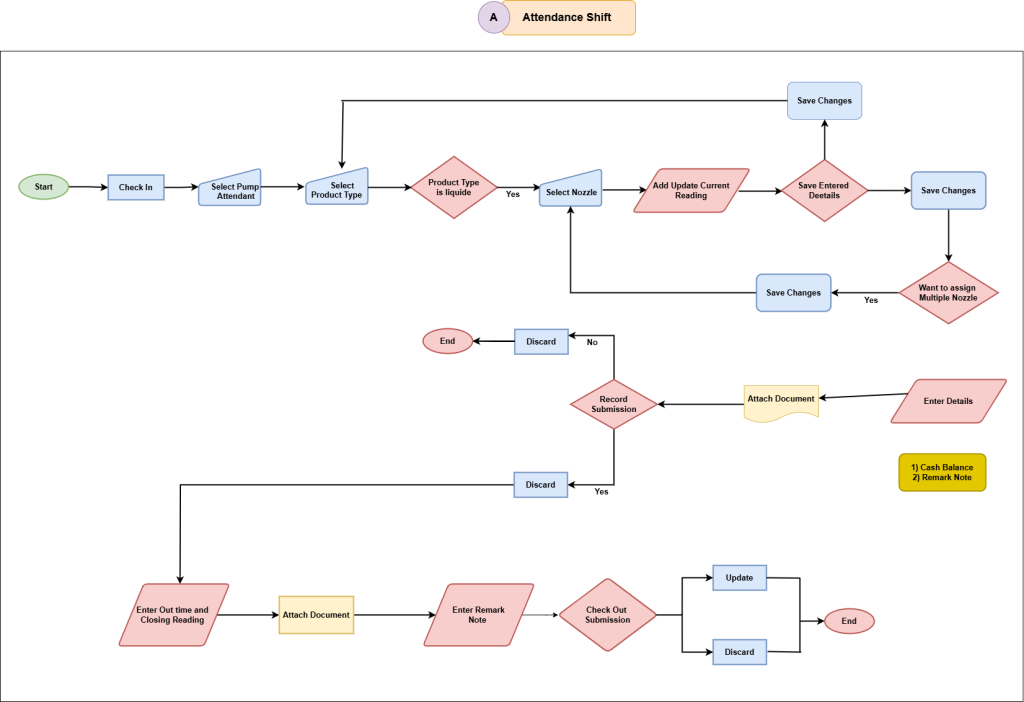

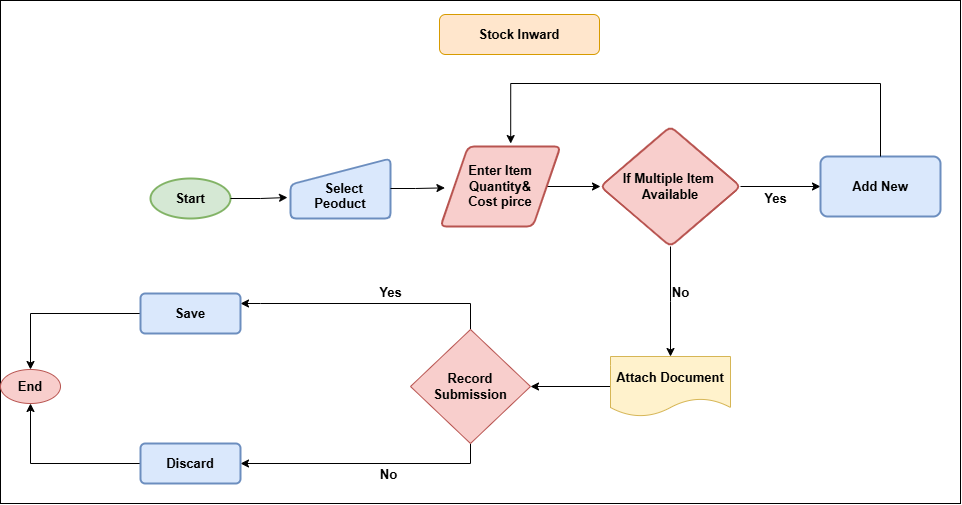

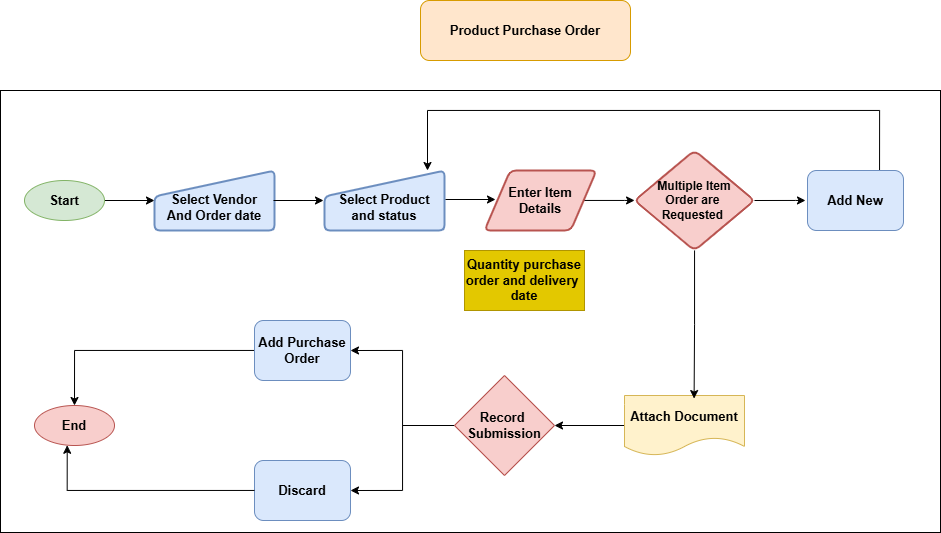

Workflow Details: Key operational workflows within the Smart Station System are meticulously detailed. The document provides step-by-step visual representations of processes, encompassing user interactions and backend operations. This ensures a comprehensive understanding of the system’s operational dynamics.

System Overview

In this section, we present a visual representation of the system overview of the product. The diagrams below offer a comprehensive view of how various modules interact to deliver a seamless and efficient user experience. The below figure depicts the system overview of the Smart Station System, offering quick insight into its structure and key elements.

Smart Station guides fuel station management seamlessly from order initiation to fuel dispensing. The Station Manager initiates a transaction, and the system accommodates flexible fueling options. This includes Full and Partial/Multiple Sales Transactions, offering precise control. The system generates receipts for partial transactions, ensuring flexibility.

Upon transaction confirmation, the Manager schedules fuel dispensing and assigns it to a pump attendant. The Smart Station system provides guidance through a mobile app, ensuring systematic fuel dispensing. The attendant manages the transaction, tracks fuel quantities, and completes the process. These events trigger immediate notifications to the Station Manager.

Upon transaction confirmation, the Manager schedules fuel dispensing and assigns it to a pump attendant. The Smart Station system provides guidance through a mobile app, ensuring systematic fuel dispensing. The attendant manages the transaction, tracks fuel quantities, and completes the process. These events trigger immediate notifications to the Station Manager.

In Smart Station, payments are manually collected by pump attendants. The system tracks manual payments, confirming sales transactions. This flexibility allows attendants to handle payments directly, catering to varied customer preferences.

As fueling progresses, the attendant initiates a closing process, complemented by the customer’s final confirmation. This officially marks the transaction as completed. Smart Station promptly reflects these crucial events, keeping the Station Manager informed in real-time.

The system facilitates tracking of manual payments and includes features for pump and inventory reconciliation. This empowers the Station Manager to manage stock levels and report discrepancies accurately, ensuring precise inventory records and enhancing overall efficiency.

System Workflows

This section provides a detailed exploration of the system workflows, offering a comprehensive understanding of the orchestrated processes that drive the seamless functioning of our system. Workflows serve as the backbone of our system architecture, delineating the step-by-step execution of tasks and the interdependencies among various components. The following workflows encapsulate the key stages and interactions within our system, ensuring optimal performance and user experience

Shift Check-In

- Pump attendants must check in at the start of their shift.

- They are required to select the product categories they are authorized to sell.

- If a pump nozzle is already assigned to another attendant, they must select an available one.

- Opening cash balance should be recorded accurately to maintain financial transparency.

- Product Type

Shift Check-Out

- Pump attendants must check out at the end of their shift.

- They should ensure that the meter out reading matches the actual quantity dispensed.

- Any discrepancies in cash balance must be reconciled and documented.

- Attendants should provide any relevant attachments or remarks for record-keeping purposes.

Location Name: Users specify the location where the stock is being received, facilitating organization and retrieval of inventory data.

Items: Users add individual items to the stock inward. For each item, the following details are provided:

The user selects the product being added to the stock from a predetermined list, ensuring clarity and consistency in inventory management.

Qty: The quantity of the product being received is specified, enabling precise tracking of stock levels.

Cost Price: The cost price per unit of the product is entered, aiding in accurate valuation of inventory.

Total: This field is automatically calculated based on the quantity and cost price provided, representing the total cost of the received quantity of the product.

Ref Code: An autofilled reference code is generated for each item, facilitating traceability and reference within the system.

Grand Total: An autofilled field displays the cumulative total cost of all added items, simplifying overall cost assessment for the received stock.

Document: Users have the option to attach relevant documents or invoices related to the stock inward, supporting thorough documentation and audit trails.

Remarks: Users can include any additional remarks or notes as needed, providing context or additional information related to the stock inward process.

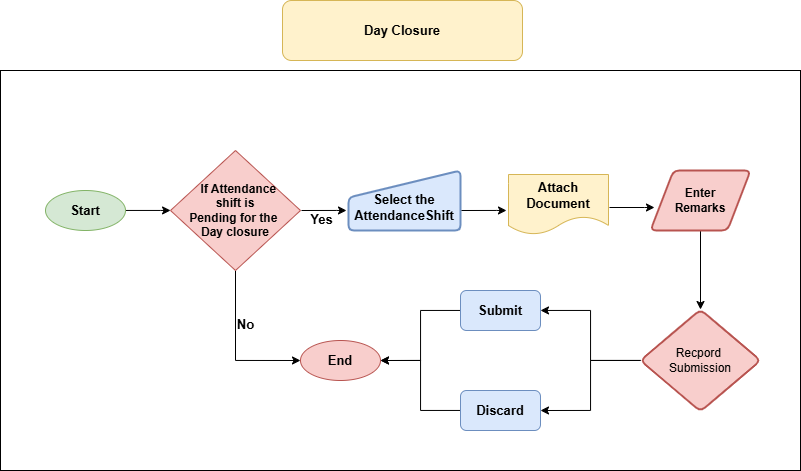

Day Closure

- The system maintains a list of daily closure reports.

- Each report includes the total amount collected, the username of the person who performed the closure, and the date & time.

- It provides a complete sales bifurcation by product, including Line Items with below details:

- Product Name,

- Online Collection,

- Cash Collection, and

- Total Sales (Online + Cash).

Purchase Order

- Purchase orders must be tracked from initiation to delivery to ensure timely replenishment of inventory.

- Users can view existing purchase orders and their delivery status within the system.

- New purchase orders can be created, specifying the required products and quantities.

- Delivery status is updated upon receipt of goods, with notifications sent to relevant user.

- Records are maintained for future reference and audit trail.

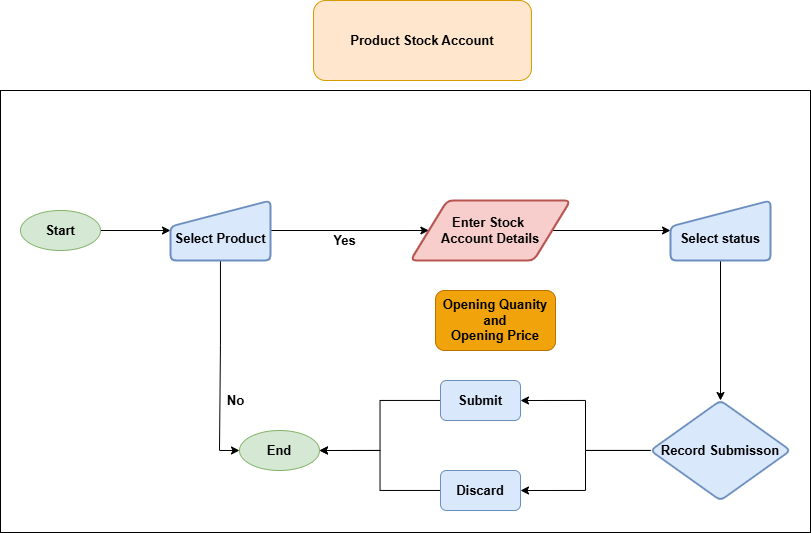

Product Stock Account

- The system allows user to add new products and update quantities and prices as required.

- Accurate stock records are maintained to prevent stockouts and overstocking.

- Product prices and quantities are updated in real-time to reflect current inventory levels.

- Transactions such as sales and stock adjustments are automatically recorded to maintain accurate inventory records.

- The system provides a comprehensive view of product stock accounts, including opening quantities, available quantities, and net quantities.

- Minimum and lowest minimum quantity thresholds can be set to trigger reorder alerts.

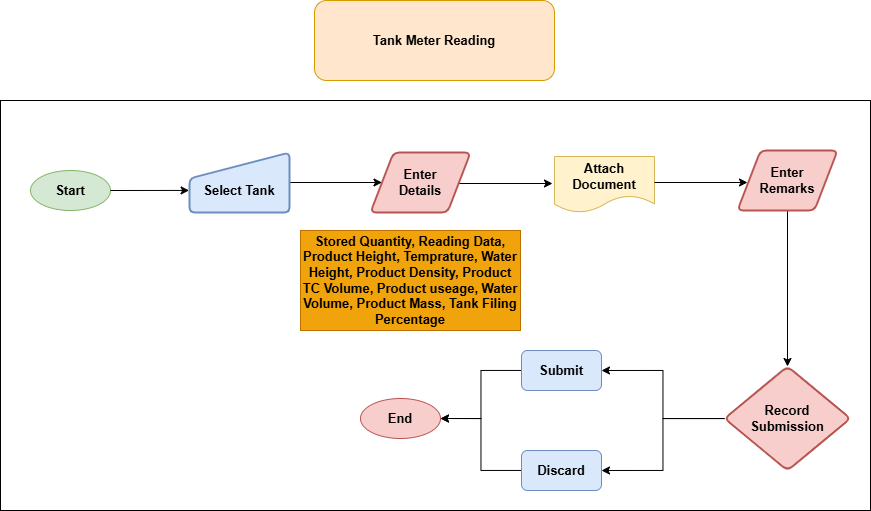

Tank Meter Reading

- Tank: The user begins by specifying the tank for which the meter reading is being recorded, ensuring precision in data organization.

- Stored Quantity: Users input the quantity of the product to be added to or present within the selected tank, providing a baseline for further calculations.

- Reading Date: Specify the date on which the meter reading is taken. This timestamp is essential for tracking changes over time.

- Product Height: The height of the product within the tank is recorded, representing its vertical occupancy within the tank space.

- Temperature: Users note the temperature of the tank at the time of the reading, acknowledging its potential impact on product characteristics.

- Water Height: The height of any water present within the tank is recorded, if relevant to the stored product or tank conditions.

- Product Density: The density of the stored product is specified, aiding in precise volume and mass calculations.

- Product TC Volume: The system calculates the total volume of the stored product within the tank, based on the recorded data.

- Product Useage: Users specify the volume of unfilled space above the stored product, providing insights into available capacity within the tank.

- Water Volume: The volume of water contained within the tank is entered, if it impacts the overall tank status.

- Product Mass: Users input the mass of the stored product within the tank, offering an additional metric for assessment.

- Tank Filling Percentage: The system automatically computes the tank filling percentage based on the recorded quantity and the tank’s capacity, simplifying assessment of utilization.

- Attachments: Users have the option to attach relevant documents or images associated with the tank meter reading, aiding in comprehensive documentation.

- Remarks: Users can include any additional comments or notes pertinent to the tank meter reading, providing context and enhancing understanding for future reference.