Quality Check Template

Purpose

The Quality Check Template module is a vital component of the quality management, designed to centralize and streamline the creation and management of quality control templates across production workflows. It provides a structured framework for defining and organizing quality checks, ensuring consistency, traceability, and compliance throughout all stages of production. By housing quality templates in a unified system, this module facilitates seamless execution of quality control procedures, enabling organizations to maintain high standards and meet both operational and regulatory requirements.

The module enhances operational efficiency by providing quick access to active templates and detailed records of past updates, making it easy to apply appropriate checks for each production scenario. By incorporating these templates into daily workflows, organizations can ensure that all products and processes adhere to consistent quality standards, reduce operational risks, and align with industry regulations.

Dependency

The Quality Check Template module is inherently dependent on the Audit Parameters module to function effectively. Audit Parameters serve as the foundational elements that define the specific quality aspects to be evaluated during inspections. These parameters are critical for configuring the Quality Check Templates, as they provide the detailed criteria and specifications needed for consistent quality assurance.

How to Navigate

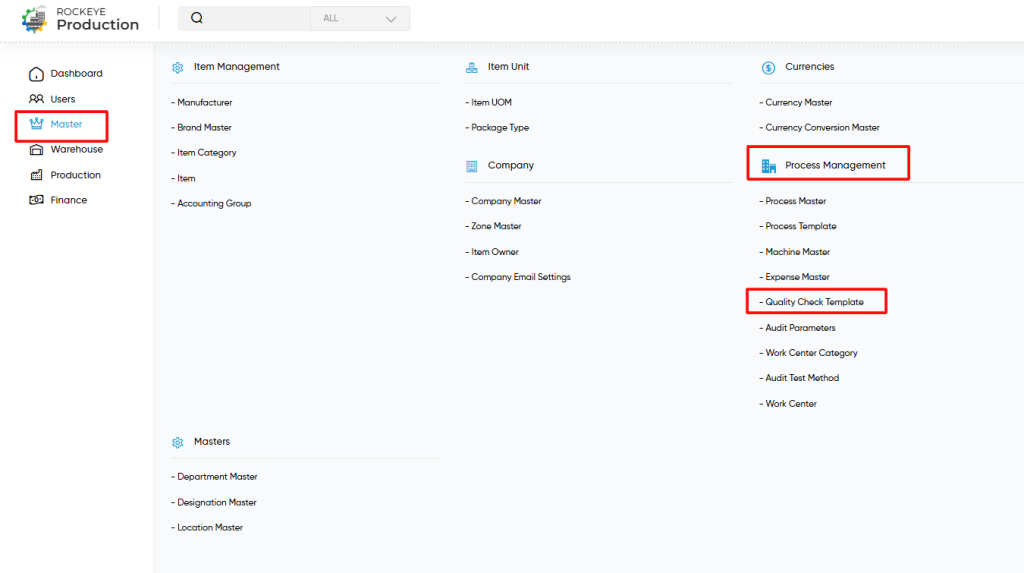

- Click on the Main Navigation Icon:

- The main navigation icon is typically located at the top right corner of the screen. Clicking on this icon will expand the navigation menu, displaying links to various sections of the production system.

- Select the Master Section:

- From the navigation menu, click on the Master section, usually located on the left-hand side. This will open a list of master modules associated with production and related operations.

- Locate the Process Management Section:

- Under the Master section, scroll down to find the Process Management category. This section contains tools and modules related to managing production processes.

- Click on the Quality Check Template Link:

- Within the Process Management section, click on the Quality Check Template. This will take you to the Quality Check Template listing screen, where you can view existing methods or create new ones.

By following these steps, users can seamlessly navigate to the Quality Check Template module, enabling them to create, edit, and manage standardized process workflows for enhanced production efficiency.

Listing

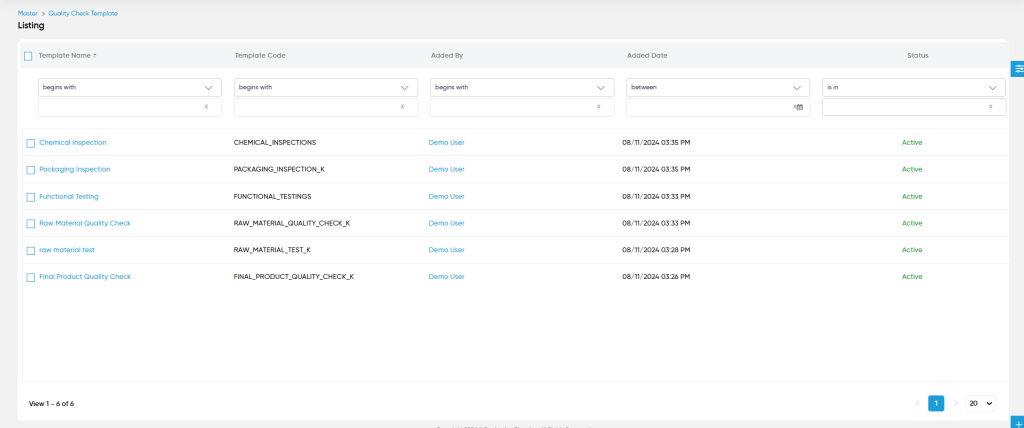

The Listing Screen serves as the central hub for managing and viewing all active and inactive Quality Check Templates within the system. This screen provides users with a structured and comprehensive view of all templates, ensuring easy access to key details and enabling efficient oversight of quality assurance processes.

Template Name:

- Displays the unique name assigned to each Quality Check Template.

- Serves as the primary identifier for users to quickly locate the required template.

Template Code:

- Each template is associated with a unique, system-generated code.

- The code enhances traceability and simplifies template referencing in other modules or reports.

Added By:

- Indicates the name of the user who created the template.

- Provides accountability and traceability by identifying the creator of each template.

Added Date:

- Captures the exact date and time when the template was created.

- Helps users track template creation timelines and maintain accurate records for audits or reviews.

Status:

- Indicates whether the template is currently active or inactive.

Pagination:

- The screen supports pagination to manage large numbers of templates.

On clicking on the specific method name a side dynamic panel will open where the user can view the brief details by clicking on the more details the user can view the details screen.

The Details Screen provides comprehensive information about a selected Quality Check Template, ensuring users have a clear and detailed view.