Dashboard

Purpose

The Dashboard provides a high-level overview of production activities and operational metrics, allowing users to quickly assess the current status of orders, batches, and production data. It offers real-time insights into critical production indicators such as pending, in-progress, and completed orders, helping users monitor progress and make informed decisions efficiently.

Total Orders

- Displays a summary of all production orders categorized by their current status (Pending, In Progress, and Completed).

- Provides users with an overview of all production orders and their current progress. This helps users track how many orders are yet to start, ongoing, or finished.

- Pending Orders: Shows the number of orders that have not yet started processing (6 orders).

- In Progress Orders: Displays the number of ongoing orders that are currently being processed (15 orders).

- Completed Orders: Reflects the number of orders that have been completed (8 orders).

Pending Orders

- Displays the number of production orders that are still awaiting action.

- Allows users to easily monitor orders that require action to begin the production process.

- Details: Lists 6 orders that are pending, covering a total of 117 units.

In Progress Orders

- Shows the number of production orders currently in progress.

- Enables users to track the status of orders that are in various stages of production.

- Lists 15 orders covering 102 units that are actively being worked on in production.

Total Production

- Displays the total number of units produced so far.

- Provides an overall picture of completed production activities and the financial value associated with the produced units.

- Shows a total production of 72 units with a total value of KES 93.73K.

Pending Batches

- Reflects the number of batch requests that are pending action.

- Helps users keep track of pending batch requests that need to be initiated.

- Displays 9 batch requests covering 24 units that are waiting to be processed.

In Progress Batches

- Shows the number of batch requests currently in progress.

- Allows users to monitor the progress of batch production and manage resources accordingly

- Displays 5 requests covering 26 units that are being processed in production.

Today’s Production

- Displays the production activity for the current day.

- Allows users to monitor production output for the current day and assess if it aligns with expected targets.

- Indicates that 0 units have been produced today, with a value of KES 0.00.

Yesterday’s Production

- Provides a summary of production output for the previous day

- Enables users to track production from the previous day, helping in the assessment of productivity over time..

- Reflects 5 units produced, valued at KES 3.04K.

Last 7 Days Production

- Summarizes production activities over the past 7 days.

- Gives users a weekly view of production performance, which is useful for assessing trends or production goals.

- Details: Shows that 16 units were produced over the last week, with a value of KES 3.89K.

Last 30 Days Production

- Summarizes production activities over the past month.

- Provides users with a monthly snapshot of production activity, which helps in long-term planning and performance tracking.

- Reflects 31 units produced in the last 30 days, valued at KES 6.23K.

Raw Material Units

- Overview: This section displays the quantity of raw materials available or consumed for production purposes.

- Allows users to track the amount and cost of raw materials required for production. This is essential for inventory planning and cost estimation.

- Unit(s): The total number of units of raw materials available or used.

- KES: The monetary value (in KES) of the raw materials in stock or consumed.

2. Semi-Finished Units

- Displays information about units that are partially processed but not yet fully manufactured (i.e., work-in-progress).

- Enables users to monitor work-in-progress (WIP) items, helping in tracking production stages and managing resource allocation for semi-finished goods.

- Unit(s): The number of semi-finished units that are currently in progress.

- KES: The value (in KES) of the semi-finished units.

3. Finished Units

- Shows details of completed production items that are fully manufactured and ready for delivery or sale.

- Provides a clear view of the total number of finished products and their financial value. This section helps in inventory management and sales readiness.

- Unit(s): The total number of finished goods available.

- KES: The total value (in KES) of these finished goods.

4. Produced Scrap

- Displays information about the quantity of unusable or discarded materials generated during the production process.

- Helps users keep track of production inefficiencies and waste management. This information is crucial for improving production processes and minimizing costs.

- Unit(s): The total number of scrap units produced.

- KES: The financial impact (in KES) associated with the scrap or wastage.

5. Recent Production Request

- Provides a summary of the most recent requests for production, including important details of the items requested.

- Provides users with a quick overview of recent production activities and helps them track the progress of each request, ensuring that all production requirements are met in a timely manner.

- Production Request Code: A unique identifier or code associated with the production request for easy tracking.

- Production Item: The name or description of the item that needs to be produced.

- Plant Name: The name of the production facility or plant where the item will be manufactured.

- Qty To Be Produced: The quantity of the item that needs to be produced.

- Production Date: The date when the production is scheduled or requested to begin.

- Estimated Total Cost: The estimated total cost (in KES) required to produce the requested quantity of items.

- Packaged Qty: The quantity of items that have already been packaged as part of this production request.

- Status: The current status of the production request (e.g., Pending, In Progress, Completed).

6. View All

- A button that allows users to view a comprehensive list of all production requests, not just the recent ones.

- Offers users the ability to dive deeper into the production pipeline, reviewing all current and historical production requests in one place for better management and decision-making.

Recent Production Batches

This section provides a summary of recent production batches, offering key details about ongoing and completed production activities.This section helps users quickly monitor the progress of recent production batches, ensuring visibility over production operations and status updates for better workflow management.

- Fields Explained:

- Production Batch Code: A unique identifier for each production batch.

- Production Request Code: The corresponding request code for the production batch, linking it to a specific production order.

- Item Name: The name of the item being produced in the batch.

- Plant Name: The facility or plant where the production batch is being processed.

- Qty To Be Produced: The quantity of the item scheduled for production in the batch.

- Status: The current status of the production batch (e.g., pending, in progress, completed).

- Order Status: Indicates the order status related to the batch (e.g., order pending, completed).

- View All: Allows users to see a complete list of production batches and their details.

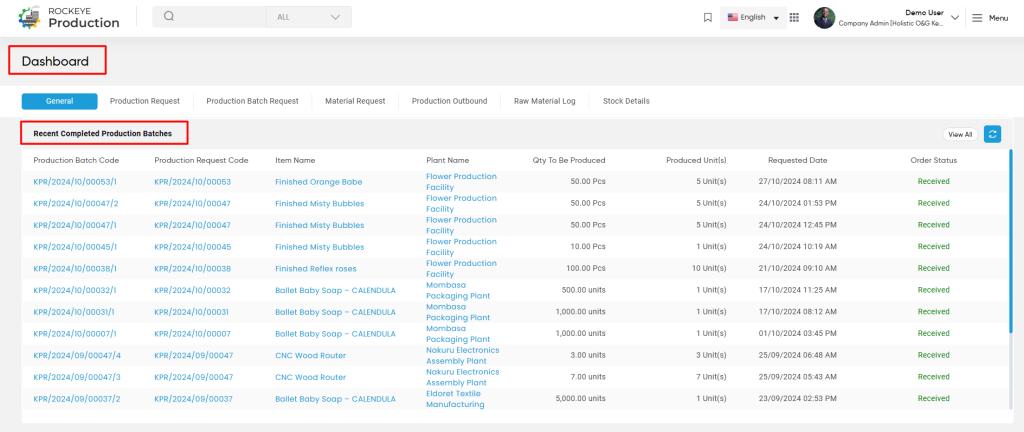

Recent Completed Production Batches

This section displays details of production batches that have been completed, providing quick access to key data such as:

- Production Batch Code: Unique identifier for the completed batch.

- Production Request Code: Linked request code for the batch.

- Item Name: Name of the item produced.

- Plant Name: Location where the production occurred.

- Qty To Be Produced: Original quantity planned for production.

- Produced Unit(s): Actual number of units produced.

- Requested Date: Date the production request was made.

- Order Status: Current status of the production order (completed).

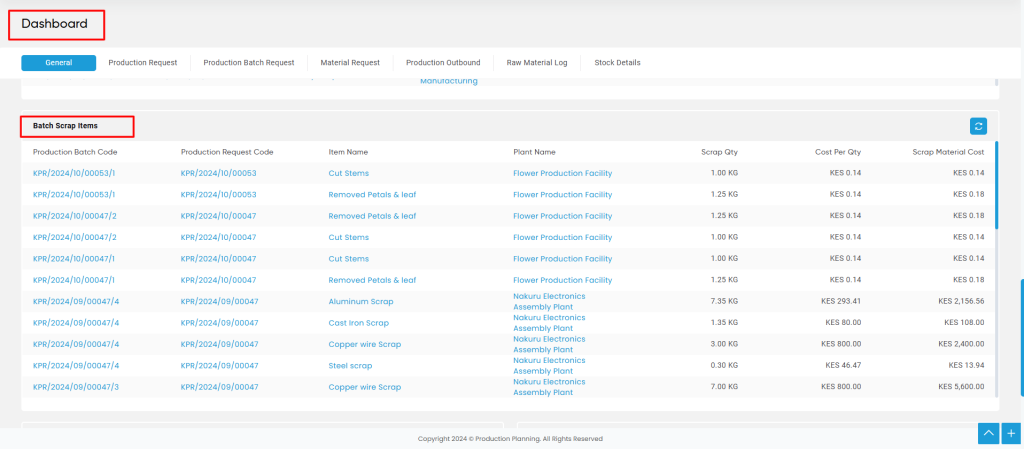

Batch Scrap Items

This section provides details on scrap items from production batches, including:

- Production Batch Code: Identifies the specific batch produced.

- Production Request Code: Reference for the production request linked to the batch.

- Item Name: The name of the item that has been scrapped.

- Plant Name: The name of the plant where production occurred.

- Scrap Quantity: The total quantity of scrap items.

- Cost Per Quantity: The cost associated with each unit of scrap.

- Scrap Material Cost: The total cost of the scrapped material.

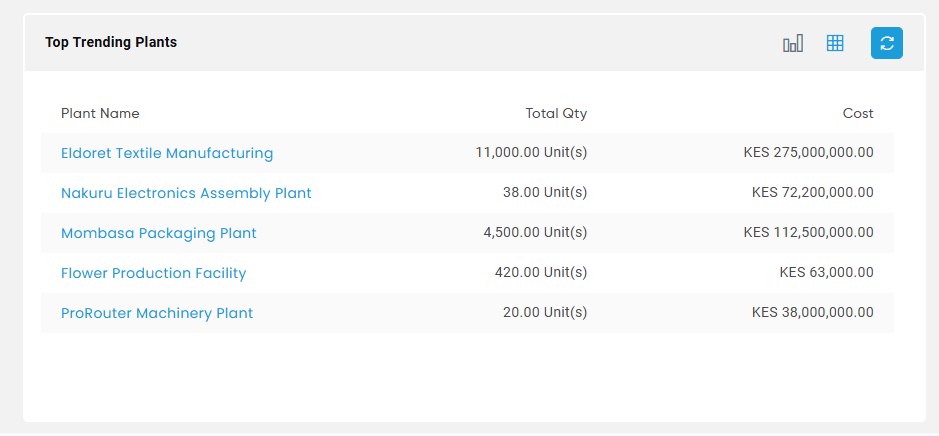

Top Trending Plant

- This section highlights the plants that are currently processing the highest volumes of production or material movement. It gives users insight into which plants are most active in terms of handling materials and associated costs.

- This section helps users understand which plants are the most operationally active, giving a quick view of the scale of production and material movement at various facilities.

- Plant Name: This column lists the names of the plants where production or material processing is taking place.

- Total Qty: This column represents the total quantity of materials being processed or handled by the respective plant.

- Cost: This column indicates the cost associated with the quantity of materials handled by each plant.

User will be able to view the Trending Plants in theb list and Chart view

Clicking on the refresh iscon will refresh the data and the updated data will be shown

Top Trending Items

- This section focuses on the warehouses managing the largest volumes of inventory. It shows which warehouses are handling the highest quantities and associated costs, giving users a snapshot of material flow.

- It allows users to see which warehouses are most involved in handling materials and their associated costs. This helps in assessing the activity levels and financial impact of different warehouse operations.

- Warehouse Name: This column lists the names of warehouses where large volumes of inventory or items are being stored or processed. Warehouses are responsible for the storage and movement of items that support plant operations or fulfill customer orders.

- Total Qty: This column shows the total quantity of items or materials currently handled by the warehouse.

- Cost: This column reflects the total cost associated with the items handled by each warehouse. Understanding the costs gives an indication of the financial value tied to the inventory.

User will be able to view the Trending Plants in theb list and Pie Chart view

Clicking on the refresh iscon will refresh the data and the updated data will be shown.

Production Tab

This tab provides a detailed overview of the Production Request section, allowing users to monitor production activities and track the status of production orders.

- Summary of Production Orders:

- Total Production Orders: Displays the total number of production orders along with the total number of units requested. For example, 36 orders with 78 units.

- Pending Orders: Shows the number of orders that are yet to be started or are awaiting approval. In this case, 6 orders with 117 units.

- In Progress Orders: Reflects the number of active production orders currently being worked on. Here, 13 orders with 82 units are in progress.

- Completed Orders: Lists orders that have been successfully completed, such as 8 orders with 55 units.

- Refresh Button:

- In each section this button allows users to manually refresh the data ,ensuring that the displayed information is up-to-date without needing to reload the entire dashboard.

- Recent Production Request:

- Displays a list of the most recent production requests, including key details as below :

- Production Request Code: A unique identifier for each production order (e.g., KPR/2024/10/00047).

- Item Name: The product or item being manufactured (e.g., “Finished Misty Bubbles”).

- Quantity to Be Produced: The total number of units requested for production.

- Customer: The client for whom the production is being carried out (e.g., “Blossom Ventures Ltd”).

- Plant Name: The production facility where the items are being produced.

- Bill of Material: The Bill of Material (BOM) associated with the production (e.g., “Misty Bouquet Assemble BOM”).

- Production Date: The date the production order was initiated.

- Status: The current status of the order, such as “Completed” or “In Progress.”

View All Button:

- This button provides users with access to a complete list of all production requests.

- Clicking on this will direct users to a detailed view page where they can see more production orders beyond the recent ones displayed in the dashboard.

Production Batch Request

Recent Production Batches section provides an overview of the latest production batch activities, allowing users to track the progress and status of individual batches associated with production requests.

- Recent Production Batches:

- This section lists recent production batches and key information about them, helping users manage and monitor ongoing production.

- View All Button:

- This button gives users access to a full list of production batches. Clicking this button will display a comprehensive view of all production batches beyond the recent ones shown on the dashboard.

- Table Contains:

- Production Batch Code: A unique identifier for each production batch. This code links specific batches to their production processes.

- Production Request Code: A reference to the original production request linked to the batch. This allows users to trace the batch back to the overarching production order.

- Warehouse Name: The name of the warehouse where the produced goods or materials are stored or where the production process is taking place.

- Plant Name: The facility or production plant where the batch is being produced.

- Production Quantity : The total quantity of items or units that were requested for production in the batch.

- Produced Quantity : The actual quantity of items that have been produced so far, providing insight into progress.

- Added Date: The date the batch was added or initiated in the system.

- Order Status: The current status of the production batch, such as “In Progress,” “Completed,” or “Pending.”

- Refresh Button:

- In each section this button allows users to manually refresh the data ,ensuring that the displayed information is up-to-date without needing to reload the entire dashboard.

Material Request

- Top Trending Plants

- This section displays a summary of the plants that are most actively involved in production or material handling. It helps users quickly identify which plants are processing the highest quantities and costs.

- Users can quickly identify the most active plants based on production volume and associated costs.

- Columns:

- Plant Name: This shows the names of plants where production or material processing is occurring.

- Total Quantity (Qty): Displays the total number of units processed at each plant.

- Cost: Reflects the associated cost for the total quantity processed by the plant.

- Top Trending Warehouses

- This section provides a list of the warehouses handling the largest volumes of inventory or material movement, along with their associated costs.

- It allows users to identify the most active warehouses in terms of material movement and value.

- Columns:

- Warehouse Name: Indicates the names of warehouses where materials or inventory are stored or processed.

- Total Quantity (Qty): Shows the total volume of items handled by each warehouse.

- Cost: Displays the total cost of materials or inventory within the warehouses.

- Recent Material Request

- This section tracks recent material requests made by plants, including the requested items, quantities, and the status of each request.

- This section helps users track and monitor material requests, providing a clear status for each, ensuring that plants receive the materials they need for production.

- Columns:

- Material Request Code: A unique identifier for each material request.

- Production Request Code: A code linked to the production process that initiated the material request.

- Plant Name: The plant that initiated the material request.

- Warehouse Name: The warehouse supplying the requested materials.

- Requested Quantity (Qty): The number of units requested.

- Total Items: Indicates the total number of distinct items requested in the material order.

- Requested Date: The date and time when the request was made.

- Request Status: Indicates the current status of the request (e.g., delivered, pending).

- Icons

- Users can refresh data or switch between different view formats (list or grid) using the control icons in each section.

- These controls ensure that users can access up-to-date information and customize the way data is presented.

Production Outbound

- Top Trending Plants

- This section highlights the plants that are currently processing the highest volumes of production or material movement. It gives users insight into which plants are most active in terms of handling materials and associated costs.

- This section helps users understand which plants are the most operationally active, giving a quick view of the scale of production and material movement at various facilities.

- Plant Name: This column lists the names of the plants where production or material processing is taking place.

- Total Qty: This column represents the total quantity of materials being processed or handled by the respective plant.

- Cost: This column indicates the cost associated with the quantity of materials handled by each plant.

- Top Trending Items

- This section focuses on the warehouses managing the largest volumes of inventory. It shows which warehouses are handling the highest quantities and associated costs, giving users a snapshot of material flow.

- It allows users to see which warehouses are most involved in handling materials and their associated costs. This helps in assessing the activity levels and financial impact of different warehouse operations.

- Warehouse Name: This column lists the names of warehouses where large volumes of inventory or items are being stored or processed. Warehouses are responsible for the storage and movement of items that support plant operations or fulfill customer orders.

- Total Qty: This column shows the total quantity of items or materials currently handled by the warehouse.

- Cost: This column reflects the total cost associated with the items handled by each warehouse. Understanding the costs gives an indication of the financial value tied to the inventory.

Recent Production Outbound

- This section provides an overview of recent outbound production activities, focusing on the movement of finished products or materials from the plant to warehouses or other destinations. It includes important details about production and transfer status.

- Production Outbound Code: This column displays a unique code for each production outbound activity, which helps in tracking specific production-related movements.

- Production Batch Code: This column shows a code associated with the batch of products or materials that are being moved out. Batch codes help trace production processes and manage the movement of specific groups of items.

- Warehouse Name: This indicates the name of the warehouse receiving or handling the outbound materials from the plant. It helps identify the destination of materials being transferred from the production facility.

- Plant Name: This column shows the name of the plant from where the materials or finished products are being moved. This helps in linking the outbound activity to the originating production site.

- Requested Date: This column shows the date and time when the transfer request was made. The date helps in tracking when the production items were scheduled for transfer.

- Transferred Qty: This column indicates the total quantity of materials or products that have been moved out of the plant.

- Order Status: This column shows the current status of the production outbound order, whether it has been completed, is in progress, or still pending.

- Purpose: This section gives users a clear view of recent production activities that involve transferring finished products or materials. It helps in tracking the status and quantities of outbound production orders to ensure that processes are completed efficiently.

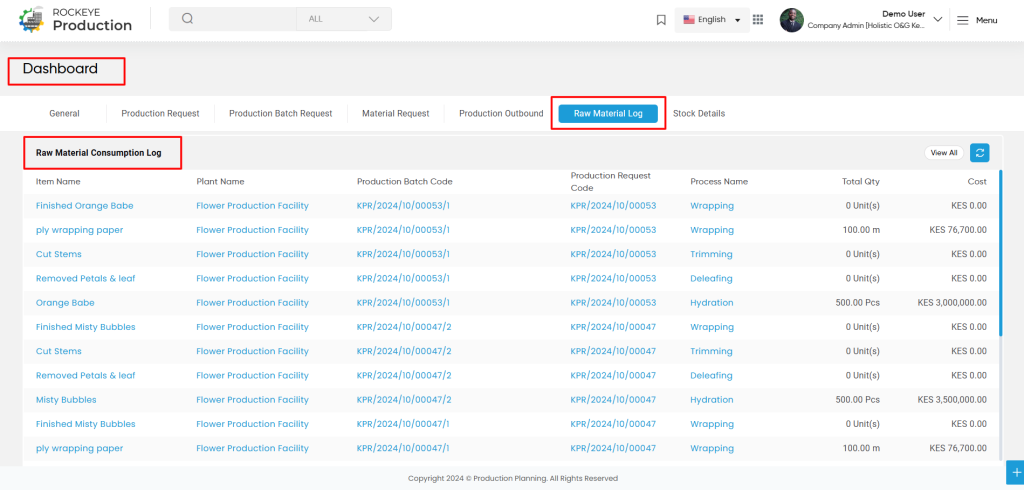

Raw Material Log

The Raw Material Consumption Log is a critical tool for production managers and inventory controllers. It provides transparency in how raw materials are being used, helps identify inefficiencies in material consumption, and ensures that inventory levels are well managed. Additionally, it aids in financial planning by showing the cost of raw materials used, allowing for better cost control and budgeting.

Overview: This section provides detailed information about the consumption of raw materials used in various production batches. It allows users to track how much raw material has been utilized, in which plant, and for which production batch or process.

- Item Name:

- The name of the raw material that has been consumed during the production process.

- Helps users identify which raw materials have been used in specific production activities.

- Plant Name:

- The name of the plant or production where the raw material was consumed.

- Provides a reference to the location where the raw material was used. This is important for tracking inventory across multiple production plants.

- Production Batch Code:

- A unique identifier or code assigned to the specific batch of production for which the raw material was used.

- Allows users to link raw material consumption to a specific batch, making it easier to track materials used in particular production runs.

- Production Request Code:

- A unique code or identifier for the production request that required the use of the raw material.

- Ties the raw material usage to a specific production request, enabling managers to see how material consumption aligns with production demand.

- Process Name:

- The name of the production process in which the raw material was consumed (e.g., cutting, molding, mixing).

- Helps in identifying the specific phase of production where the raw material was used, allowing for better analysis of resource allocation.

- Total Qty:

- The total quantity of the raw material that was consumed for the specific production batch and process.

- Gives a clear understanding of the amount of raw material used, which helps in inventory planning and controlling material waste.

- Cost:

- The total cost of the raw material consumed in the production process.

- Provides financial insight into the cost of materials used in production, which is crucial for calculating the total production cost and for cost analysis.

View All:

- Allows users to view all entries related to raw material consumption, not just the current or most recent ones.

- Offers users a detailed history of raw material consumption across all production batches, processes, and requests.

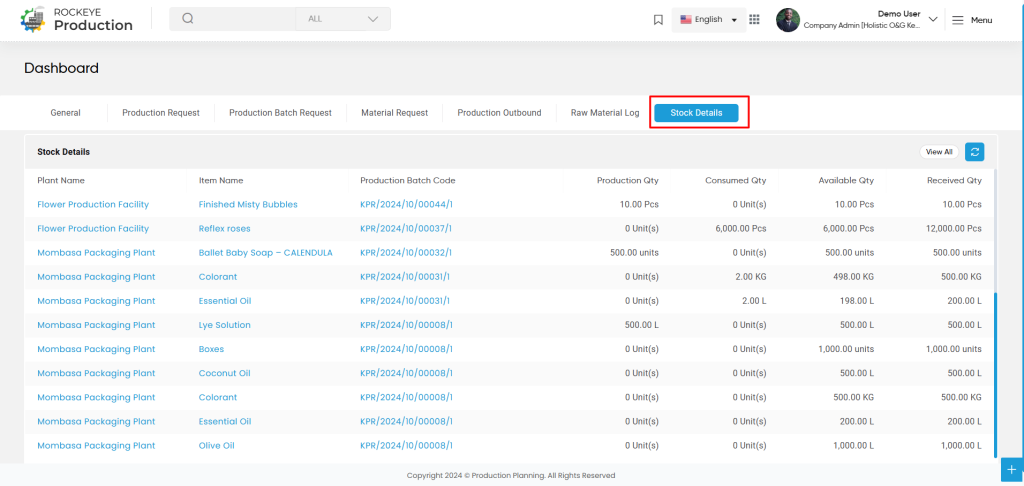

Stock Details

- The Stock Details section provides comprehensive data regarding the quantity and status of items in stock across various production batches and plants. It tracks the movement of materials, from production to consumption, giving a real-time overview of stock availability.

- Plant Name:

- The name of the plant or production facility where the item stock is being managed.

- Helps users track stock levels for specific plants, allowing for better inventory control and resource allocation across multiple locations.

- Item Name:

- The name of the item (raw material, semi-finished product, or finished product) that is being tracked.

- Enables identification of the specific item in stock. This is essential for managing multiple types of items within a production environment.

- Production Batch Code:

- A unique identifier for the specific production batch in which the item was produced or used.

- Links stock information to a specific batch, helping users track inventory associated with particular production batches, which aids in quality control and traceability.

- Production Qty:

- The quantity of the item produced in a specific batch.

- Provides a record of how much of the item was produced during the production process, helping users to track output.

- Consumed Qty:

- The quantity of the item that has been consumed or used in further production processes.

- This field helps in monitoring how much of the produced stock has already been used, allowing for better material planning and minimizing stock shortages.

- Available Qty:

- The quantity of the item currently available in stock after accounting for consumption and received stock.

- This is critical for ensuring that sufficient stock is available to meet ongoing production needs. Users rely on this information to determine when to order more materials or produce more items.

- Received Qty:

- The quantity of the item that has been received or added to stock, either from production or external sources.

- Tracks new stock added to inventory, whether through production or purchasing. This helps in monitoring stock inflows and maintaining accurate inventory levels.

- Plant Name:

- View All:

- A link or button that allows users to view all stock entries related to the items across all plants and batches.

- This provides users with a complete view of all stock details, not just the most recent entries. It helps in conducting thorough inventory audits, reviewing stock history, and managing stock across multiple plants.

- Refresh

- In each section this button allows users to manually refresh the data ,ensuring that the displayed information is up-to-date without needing to reload the entire dashboard.