Material Master

Introduction/Purpose:

The material master is a central component that holds detailed information about the materials or products that an organisation procures, produces, or sells. It serves as a master data record for all materials within an organisation and plays a crucial role in various procurement processes.

The Material Master entry contains comprehensive information about a specific material, including its description, classification, attributes, pricing, units of measure, stock availability, and procurement details. It acts as a single source of truth for all material-related data, ensuring consistency and accuracy across different departments and functions.

How to Navigate:

The navigation to record a material master in a procurement system typically involves the following steps:

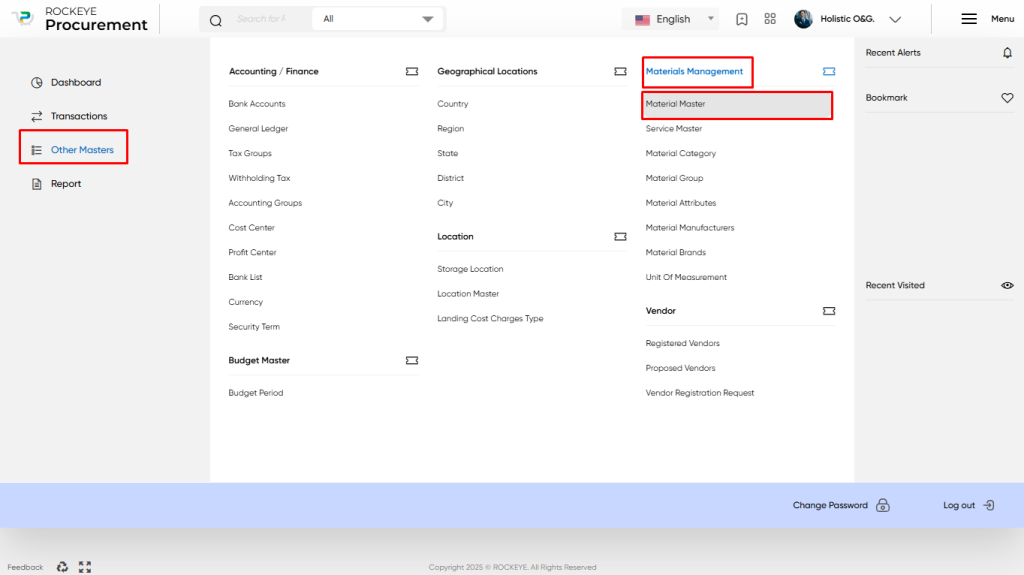

- Click on the main navigation icon: The main navigation icon may be located in the top right corner of the screen. Clicking on this icon will open the navigation menu, which typically includes links to various sections of the procurement system.

- Click on the Other Master section: The Other Master section is located under the left section of the screen; clicking on this section will display a list of masters related to procuring.

- Find the Materials Management section: The Materials Management section is located in the list of Masters under the Master section. Clicking on this section will display a list of masters related to materials management.

- Click on the Material Master link: The Material Master link is located under the Materials Management section. After clicking on this link, you can navigate to Material Master in the listing, and from that, you can easily upload new transactions into the system.

Listing:

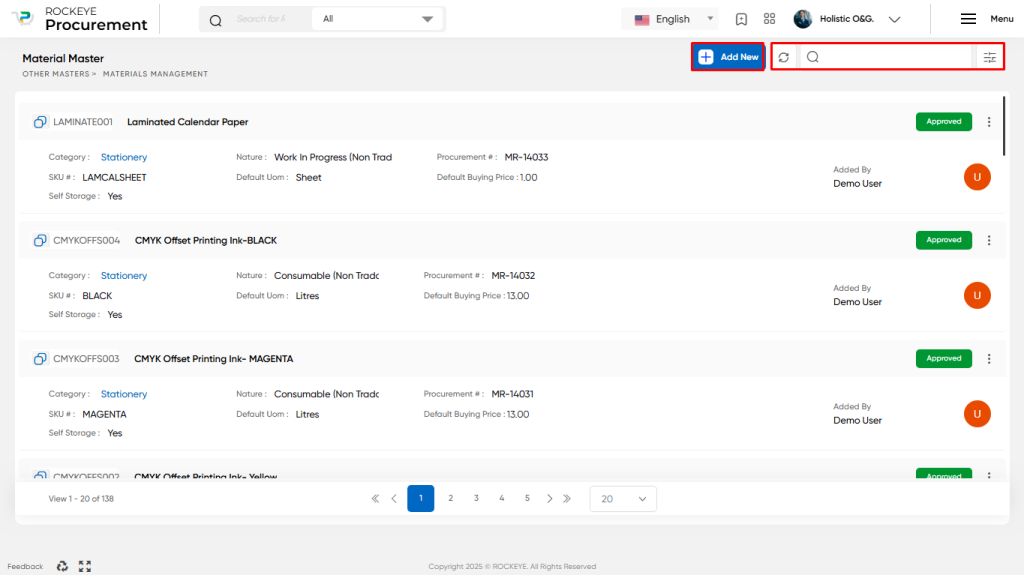

Material Master is a critical aspect of procurement, and segregating Material Master listings based on their status can help manage the material process efficiently. Here is how material master listings can be segregated into different categories:

- Record Filter: The Material Master listing may include a filter option that allows users to filter the list of Material Master based on specific criteria, such as Material Name, Inventory Code, Ref Code, Unit of Measurement, Material Type, Approval Status, Status SKU Code, Material Code, and Category.

- Transaction Search: The Material Master listing may include a search function that allows users to search for a specific Material Master by material number or other keywords.

- Listing view: The Material Master listing may display each order in a card format view that includes key information such as material name, material code, SKU code, category, unit of measurement, material type, approval status, and status.

In summary, by incorporating the Material Code filtering functionality during the recording process, users can easily search and identify existing Material Masters based on their unique code, ensuring data integrity and minimising duplication. This approach simplifies the recording process by narrowing down the options to the specific material being recorded, saving time and improving data accuracy.

Recording & Update:

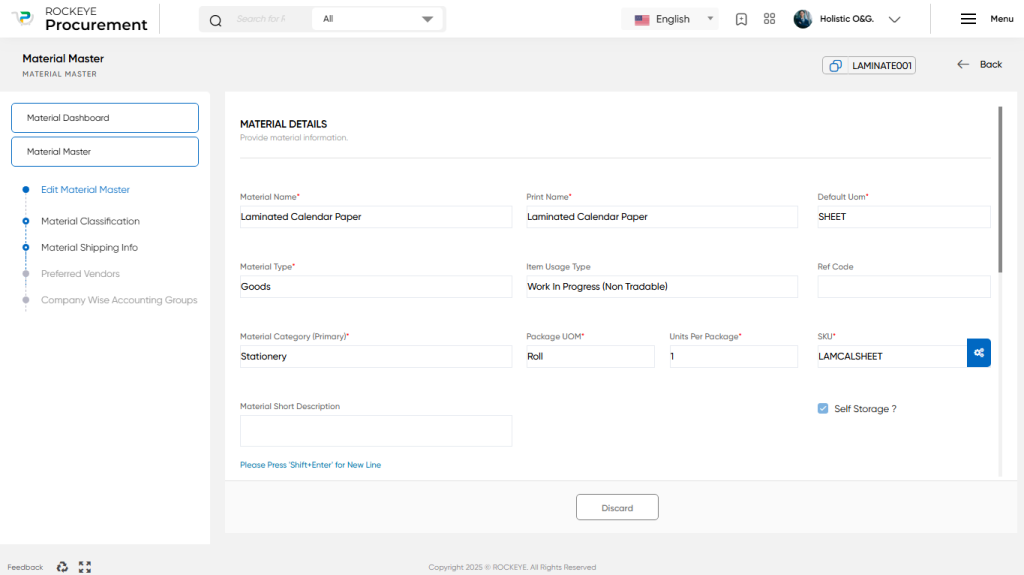

Material Master is an essential part of the procurement process, which involves Recording and updating Material Master data involves capturing and maintaining comprehensive information about materials within the procurement system. Here’s an overview of the process:

- Material Name: The name or description of the material for identification and reference purposes.

- Print Name: The name of the material as it should appear in printed documents or reports.

- Default Unit of Measurement: The base unit of measurement for the material, such as pieces, kilograms, liters, etc.

- Material Type: The classification or type of material, such as finished goods, raw materials, spare parts, or services.

- Item Usage Type: The intended usage or purpose of the material within the procurement system or organisation.

- Material Category (Primary): The primary category or group to which the material belongs. This helps in organising and categorising materials for easier management and analysis.

- Package UOM (Unit of Measurement): The unit of measurement used for packaging the material, if applicable. This can be different from the default unit of measurement.

- Units Per Package: The number of units contained in each package, if the material is packaged in a specific quantity.

- SKU Code: A unique Stock Keeping Unit (SKU) code or identifier assigned to the material for inventory tracking and identification purposes.

- Material Short Description: A concise description of the material that provides additional information or details.

- Accounting Group: Select the appropriate accounting group for the material based on whether it is purchasable and if its inventory needs to be tracked. This helps in determining the material’s financial treatment and accounting processes.

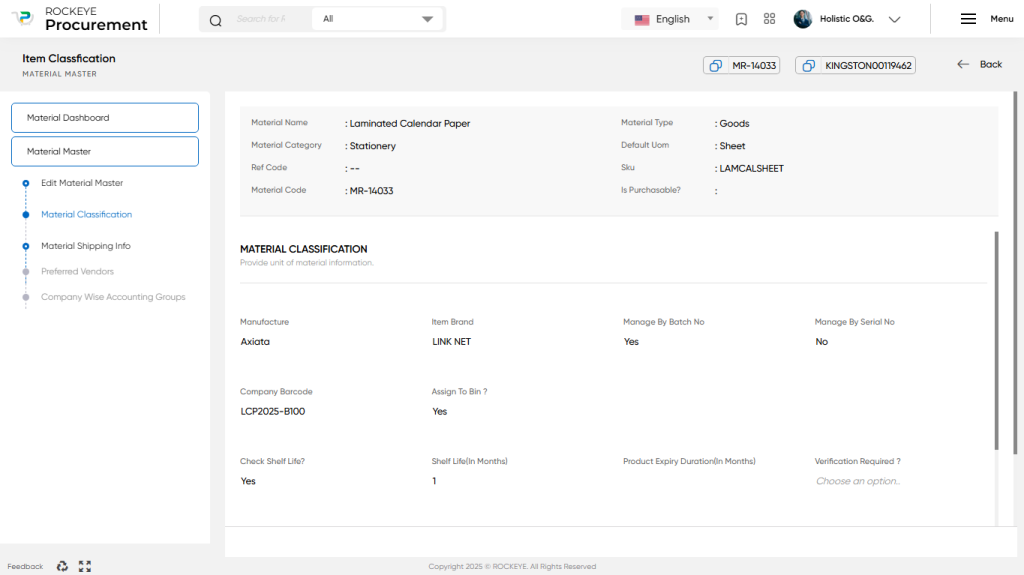

- Material Classification: Specify additional classification information for the material, such as the manufacturer, brand, batch, or serial number, and whether it has a defined shelf life.

- Cost Price: Enter the cost price of the material in the local currency and, if applicable, in a foreign currency if it is sourced from abroad.

These mandatory fields help ensure that essential information about the material is captured accurately in the procurement system, enabling effective procurement and inventory management processes. Additional fields or attributes may also be available depending on the specific requirements of the procurement system or the organisation’s needs.

The user can perform the following actions in this section:

- Submit: This option allows the user to publish the transaction information. If the system has an approval flow, the maker will submit the information, and it will be sent to the approval authority or checker for approval.

- Discard: This option allows the user to discard the transaction before saving it.

Key Notes Material Master:

- The Material Master Dashboard provides a centralised view of data, including warehouse-wise low stock, open purchase orders, price comparison (highest, lowest, average, and last purchase price), and more.

- Material masters will be linked and Sync with the inventory module (if it’s Enabled)