Maintenance & Service

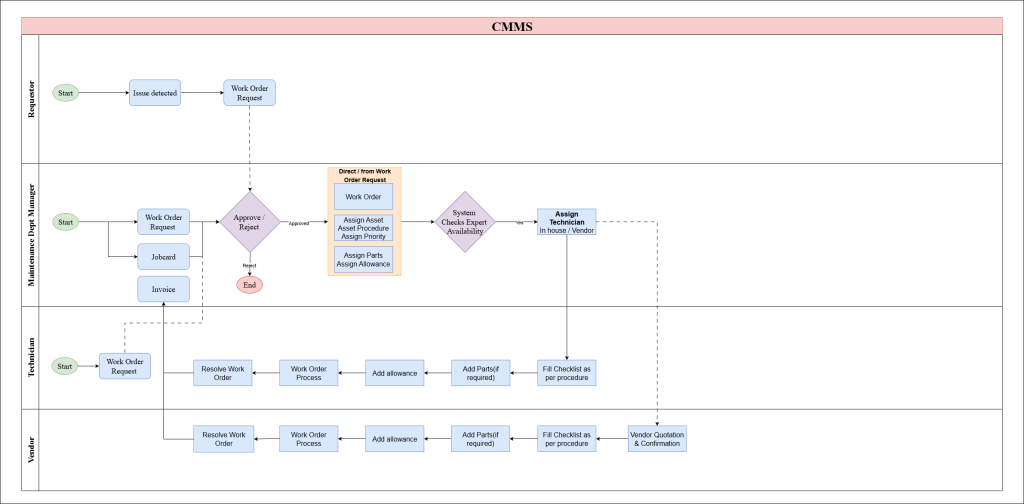

The CMMS module consists of several tightly integrated components, each playing a crucial role in delivering a full maintenance cycle. Below is a detailed explanation of these entities and how they interact:

Asset

The core element of the CMMS. Every work order, maintenance job, or checklist revolves around one or more assets. The system maintains a detailed record of each asset, including type, location, usage history, maintenance procedures, assigned technicians, warranty information, and part consumption. Asset hierarchy (e.g., main machine with subcomponents) can also be configured.

Work Order Request

Raised by any authorized department when an asset issue is identified. The request includes information about the asset, issue description, urgency, and possible location. This entity kicks off the entire maintenance workflow.

Work Order

Generated only after a manager’s approval of the Work Order Request. It includes comprehensive data such as the asset involved, assigned maintenance procedures, criticality level (priority), predefined parts needed, and budget or part allowance. The Work Order serves as the central transaction tying together asset info, technicians, parts, procedures, and financials.

Approval Workflow

The Maintenance Manager reviews incoming work order requests and decides whether to approve or reject. If rejected, the process terminates. Upon approval, the system creates a formal work order with all relevant details.

Jobcard

For logistics or department-specific asset repairs, a jobcard may be generated. This supports the separation of high-volume department-level maintenance. If a jobcard is used, the invoice is auto-generated upon closure of the work order.

Technician Assignment

Once a work order is active, the system checks the availability of internal technicians or approved external vendors. Based on priority, specialization, and availability, a technician is auto-assigned or manually selected. The technician receives all necessary information including asset details, parts allocated, and step-by-step procedures.

Vendor Handling

If outsourced, the vendor is sent a work order invitation. They may respond with a quotation and confirm job acceptance. From there, they proceed through the same flow as internal technicians — filling checklists, updating work progress, and requesting additional parts or allowance if needed.

Checklist

Each maintenance procedure has a linked checklist to ensure procedural compliance. Technicians or vendors must follow and complete this checklist before submitting work order completion. This also enables the system to validate quality and coverage before closing the order.

Parts & Allowance Management

Parts and allowances (fixed or variable) are pre-assigned at the work order level. If additional parts are needed during execution, the technician can raise a request which is then approved inline or post-validated. This ensures parts traceability and cost control across each job.

Work Order Process

This represents the live execution phase of maintenance. Includes technician actions such as starting work, recording downtime, adding remarks, consuming parts, and closing checklist items. Once all steps are marked complete, the work is marked for closure.

Work Order Closure

Upon successful completion and checklist validation, the technician/vendor closes the work order. If a jobcard is present, the system automatically generates an invoice. The manager can then review reports and asset logs for final closure.

System Automation & Status Tracking

The CMMS includes automated status updates — such as Open, In Progress, On Hold, Completed, or Rejected. These states help managers and auditors instantly see where each work order stands and how resources are performing.

The CMMS module involves multiple stakeholders who interact with the system at different stages of the maintenance & service lifecycle. Each role is mapped to specific responsibilities to ensure accountability, traceability, and efficient coordination across departments and external vendors.

1. Requestor

Typical Role: Department Staff

Responsibility Summary: Initiates the maintenance process by reporting an issue.

Key Responsibilities:

- Detects faults or maintenance needs in an asset.

- Logs the issue by raising a Work Order Request in the system.

- Selects the concerned asset and provides relevant issue details (e.g., work order, priority, location).

- May attach supporting media (images, videos) for better understanding.

- Tracks the status of their request (e.g., Pending Approval, In Progress, Completed).

2. Maintenance Department Manager

Typical Role: Workshop Manager, Maintenance Manager

Responsibility Summary: Owns the approval and supervision of the entire work order lifecycle.

Key Responsibilities:

- Reviews and approves or rejects incoming Work Order Requests.

- Upon approval, triggers the creation of a Work Order.

- Assigns:

- The asset and relevant maintenance procedure.

- Parts and materials required.

- Priority level based on criticality.

- Any allowance to technicians or vendors.

- Monitors technician/vendor availability and initiates assignment accordingly.

- Oversees the execution of maintenance tasks through status tracking (e.g., In Progress, On Hold).

- Validates checklist completion, part usage, and technician remarks.

- Reviews invoices (if jobcard-based) before approving payment.

3. Technician (In-house)

Typical Role: Internal Maintenance Staff, Electrician, Mechanical Technician

Responsibility Summary: Executes the assigned work orders and ensures asset repair or servicing is completed per standards.

Key Responsibilities:

- Receives system notification upon being assigned a Work Order.

- Reviews asset details, procedure steps, assigned parts, and checklist.

- Accepts the job and initiates the Work Order Process.

- Conducts physical inspection and performs repair/maintenance per the defined procedure.

- Updates the system with progress, downtime if any, and part usage.

- Requests for additional parts or allowance if needed (requires approval).

- Completes the checklist to verify work done and procedure compliance.

- Submits remarks, photos, or documents (if enabled).

- Marks the work order as Resolved upon completion.

4. Vendor (External Technician)

Typical Role: External Technician

Responsibility Summary: Handles outsourced maintenance jobs through vendor-managed workflows.

Key Responsibilities:

- Receives a work order invitation with full job details.

- May be required to submit a quotation for approval.

- Once approved, accepts the job and begins execution.

- Accesses asset procedure, checklist, and part/allowance details from the system.

- Fills out the checklist as per the maintenance standards.

- Requests for extra parts or budget allowances (if required).

- Uploads necessary documentation or evidence of work done.

- Completes and submits the Vendor Work Order Process.

- Work order is marked as Resolved and sent for final review and closure by internal manager.

- Invoice is generated for payment based on agreed terms (linked with jobcard if applicable).